You might not be able to identify the difference between LED tube lighting and tubular fluorescent lighting unless you operate in the lighting business. The tubes appear identical at first sight, however, there are significant distinctions between the two types of tubes. We’ll give you an insider’s perspective by examining why are LED tube lights better as compared to fluorescent lights.

LED Tube Lighting

Components: LED tube lighting has an aluminium structure, a plastic lens, and strong electrical components that allow for cutting-edge functionality. LED tubes are identified as things that are free of lead, mercury, and other harmful elements, making this tube secure for everyone in the unlikely case that it breaks. Fluorescent tube lights, that contain toxic substances such as mercury, are now used in the majority of offices. When rid of in landfill garbage, this will pollute the ecosystem. Because removal must be organised through a licenced waste carrier, moving to LED avoids the expense and time constraints of compliance disposal – and assist to preserve the environment from further hazardous waste.

Longevity:

LED tubes have a considerably longer lifespan than typical fluorescent bulbs. According to current LED specifications, LEDs can withstand over 50,000 hours of testing. This means that an LED tube will return for itself in the long run. LEPRO is confident in the durability of our tubular goods and provides a standard guarantee on the majority of our LED tubes. LED helps to reduce carbon emissions. LED tube lights have a lifespan of up to six times that of conventional types of lighting, eliminating the need for regular replacements. As a consequence, fewer lights are used, and hence fewer resources are required for production operations, packing materials, and shipping.

Recyclability:

LED tubes are completely recyclable! The tube must be disassembled in order to be fully recycled. You may recycle metal and plastic at your local recycling centre, and electrical components can be recycled at a computer or e-cycling site.

Efficiency:

On average, the cost of power usage accounts for 15% of a company’s budget. LED lighting, due to its economy, has the potential to significantly reduce expenses. Now some latest LEDs use 26 watts and produce 3300 lumens, equivalent to almost 129 lumens per watt (lm/w)! That’s a lot of clarity for such a small amount of power. Also, LED lighting is up to 75% more efficient than conventional lighting like fluorescent and incandescent bulbs. Only 5% of the energy in LEDs is lost as heat, while the other 95% is turned into light. In comparison, fluorescent lights convert 95 per cent of their energy to heat and only 5 per cent to light! LED lights consumes less amount of energy than conventional lighting; a standard 84-watt fluorescent can be replaced with a 30-watt LED to produce the same amount of light. Lower electricity use reduces demand for power plants and minimises greenhouse gases.

Installation:

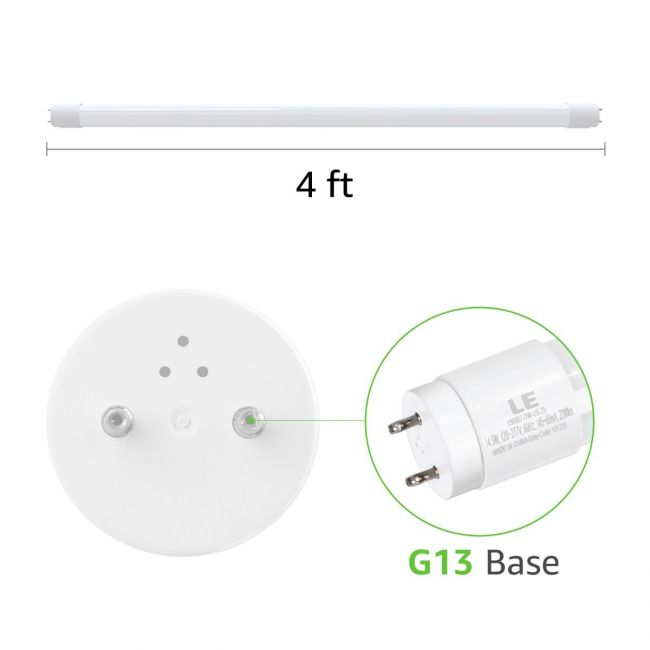

It has never been simple to facilitate the shift to LED tubes! LEPRO enables retrofitting LED tubes that fit in your present fluorescent fixtures that use ballasts. Our most popular tubular product makes use of our direct-wire installation method. This kind of installation eliminates the need for extra wattage by bypassing the ballast and running the wire straight into the mainline through non-shunted lamp holders that secure the LED tubes in the fixture. For system upgrades, LEPRO now provides tubular LED fixtures that are suitable with all of our T8 and T12 LED tubes.

Cold temperature:

LEDs, unlike fluorescent bulbs, enjoy the chill. Fluorescent lights require more voltage to begin at low temperatures, and their luminous flux decreases. On the other hand , LED performance goes high when operational temperatures fall. As a result, LEDs are an excellent choice for chilled display cases, refrigerators, and cold storage areas, as well as exterior applications such as parking lots, building perimeters, and signs. DOE testing of an LED refrigerated case find a 5.1% increase in effectiveness at -5°C as measure at 25°C.

Instant ON:

Most fluorescent and Halogen lights do not produce full brightness as soon as they are turned on, with many taking three minutes or longer to attain maximum light output. LEDs, on the other hand, turn on at full brightness practically instantaneously and with no re-strike delay. This can be useful after a power loss or whenever personnel open a facility in the early hours while it is still dark outside.

Controllability:

Making industrial fluorescent lighting systems dimmable can cost and over a few dollars, while LEDs, being semiconductor devices, are naturally controllable. Some LEDs can even be lowered to 10% of their maximum brightness, whereas typical fluorescent lights only reach around 30% of their maximum intensity. LEDs also provide constant dimming rather than step-level dimming where 100 to 10 per cent light output is seamless. To check the latest type of LEDs visit ceiling tube light.